Support

Adelino Duarte da Mota S. A.

COMPETE 2020- mSCM

Project Designation | mSCM: Mobile Technologies for the Ceramic Raw Materials Supply Chain

Project Code | POCI-01-0247-FEDER-016379

Main Objective | 1 – Strengthen research, technological development and innovation

Region of Intervention | Portugal

Beneficiary Entity | Adelino Duarte da Mota, SA

Approval Date | 19-02-2016

Start Date | 04-03-2016

End Date | 04-03-2017

Total Eligible Cost | €20,000

European Union Financial Support | FEDER – €15,000

Objectives, activities and expected/achieved results

This R&D project focuses on 3 fundamental areas, namely, Information and Electronic Communication Technologies (ICT), Materials and Systems Engineering.

It is an mSCM (mobile supply chain management) project that focuses on mobile technologies for the supply chain of ceramic raw materials at Adelino Duarte da Mota, S.A.

As specified, the objective was (1) to investigate how to implement mobile technologies in a leading company in the ceramic raw materials industry, as well as (2) to develop a pilot solution.

The expected results were fully achieved, namely the development of a pilot solution based on an approach developed specifically for the competitive context of ADM.

Adelino Duarte da Mota S. A.

Compete 2020- M2G2

M2G2 – Development of new stoneware pieces with higher added value through more sustainable processes.

Project Code: POCI-01-0247-FEDER-017993

Support: Research and Technological Development Incentive System (SI ID&T) | Business R&D – Co-promotion Projects – Call for Proposals 33/SI/2015

Leading entity: RIA STONE, FÁBRICA DE LOUÇA DE MESA EM GRÉS, S.A.

Co-promoters: UNIVERSIDADE DE AVEIRO | VITRICER – FRITAS E VIDROS CERÂMICOS, LDA| ADELINO DUARTE DA MOTA S.A.

Objective: OT 1 – Strengthen research, technological development and innovation.

Project Location: NUTS II – CENTER

Approval Date: 23/08/2016

Start Date: 01/09/2016

End date: 31/08/2019

Amounts involved:

• Total Investment: 1,691,543.44 Euros

• Total Eligible Investment: €1,666,900.25

• Financial Support (Non-Refundable Incentive): ERDF €1,073,424.51

Project summary:

The “M2G2” project is promoted by a consortium formed by the companies Ria Stone, Adelino Duarte da Mota,

and Vitricer, together with the Research Center for Ceramic and Composite Materials of the University of Aveiro.

Its objective is to develop new, high-value-added stoneware pieces using significantly improved pastes and glazes

and new decoration techniques, through a more economically and environmentally sustainable process.

The aim is to develop a new product that overcomes the current limitations of stoneware tableware technical

characteristics, particularly the phenomenon of metal-marking, resistance to detergent attack, and the limited

range of decorative options.

With the M2G2 project, Ria Stone intends to change the paradigm of its relationship with IKEA, moving away

from price-based competition and introducing the possibility of suggesting new, differentiated products with

new designs through the use of more sustainable production processes.

Activities:

1. Preliminary studies and technical specifications;

2. Laboratory research/development;

3. Design and development;

4. Prototype construction / Testing and trials;

5. Promotion and dissemination of results;

6. Technical project management.

Expected Results:

• Thin stoneware pieces (but with high mechanical strength).

• Ceramic pastes for stoneware with low water absorption;

• Opaque glazes with high resistance to metal marking;

• High-performance stoneware pieces in service, at the metal-marking level;

•High-performance stoneware pieces in service, at the level of gloss;

• A diverse range of colors in the decor;

• Decoration by digital printing;

• Stoneware pieces produced using low firing temperatures;

• Stoneware pieces produced using short firing cycles.

Project designation | mSCM: Mobile technologies for the ceramic raw materials production chain

Project code | POCI-01-0247-FEDER-016379

Main objective | 1 – Strengthen research, technological development and innovation.

Intervention Region | Portugal

Beneficiary entity | Adelino Duarte da Mota, S.A.

Approval date | 19-02-2016

Start date | 04-03-2016

Completion date | 04-03-2017

Total eligible cost | 20.000 €

Financial support from the European Union | FEDER – 15.000 €

Objectives, activities and expected/achieved results

This R&D project focuses on 3 fundamental areas, namely, Information and Electronic

Communication Technologies (ICT), Materials and Systems Engineering.

It is an mSCM (mobile supply chain management) project that focuses on mobile technologies

for the supply chain of ceramic raw materials at Adelino Duarte da Mota, S.A.

As specified, the objective was (1) to investigate how to implement mobile technologies

in a leading company in the ceramic raw materials industry, as well as (2) to develop a pilot solution.

The expected results were fully achieved, namely the development of a pilot solution based on

an approach developed specifically for the competitive context of ADM.

Adelino Duarte da Mota S. A.

Life eddshellence

Project designation | Eggshell: a potential raw material for CEramic wall tiles (LIFE EggshellenCE)

Project code | LIFE19 ENV/ES/000121

Main objective | Resource efficiency, including soil and forests, as well as promoting a circular economy.

Intervention Region | Portugal and Spain

Beneficiary entity | Asociación de Investigación de las Industrias Cerámicas; Adelino Duarte da Mota, S.A. (MSC); Agotzaina, S.L.; Euroatomizado, S.A.; Maincer, S.L.; Universidade de Aveiro;

Link to the LIFE EGGSHELLENCE project website. | https://www.lifeeggshellence.eu/

Approval date | 2020-06-17

Start date | 2020-10-01

Completion date | 2023-09-30

Objectives, activities and expected/achieved results

The project idea stems from an issue identified in the egg processing industry, related to the amount of waste generated (shells) and the environmental impact this situation causes. This, combined with the need to conserve virgin and non-renewable raw materials, and the experience gained by the project partners in ceramic transformation involving the valorization of waste, where the company ADM shares extensive experience acquired over the last few years, led to the development of a more comprehensive approach.

The main objective of the project is to demonstrate the technical feasibility of using eggshells as a secondary raw material in the production of ceramic coatings. The success of the project will result in economic benefits for both the egg processing and ceramic industries, as well as environmental benefits, since it will contribute to the application of the Waste Framework Directive (Directive 2008/98/EC) for a resource-efficient Europe.

The LIFE EggshellenCE project aims to implement the concept of a circular economy through industrial symbiosis between egg processing companies and ceramic companies. To develop a prototype for eggshell pretreatment that separates the membrane from the eggshell through a simple and low-cost process; to verify the absence of environmental impact from the use of eggshell in the production of ceramic coating compositions, as well as in the membrane separation process; to develop a new business model for the egg processing industry as a supplier to the ceramic industry.

Felmica Minerais Industriais S. A.

Centro 2020- Productive Innovation

Project designation | PRODUCTIVE INNOVATION: +VALUE – Increasing Felmica's production capacity, with a view to producing mineral compounds with higher added value, in a sustainable way.

Project code | CENTRO-02-0853-FEDER-000748

Main objectivel | 3 – Strengthening the competitiveness of SMEs

Intervention Region | Center

Beneficiary entity | FELMICA MINERAIS INDÚSTRIAIS S.A.

Approval date | 10-08-2015

Start date | 01-07-2015

Completion date | 30-06-2017

Total eligible cost | 1.299.000,00 €

Financial support from the European Union | 779.400,00 €

Objectives, activities and expected/achieved results

The project, designated as "+VALOR – Increasing Felmica's production capacity, aiming at the production of mineral

compounds with higher added value, in a sustainable way," and framed within the Productive Capacity Increase

typology, foresees "investments focused on technological innovation," both at the manufacturing process level

and at the level of new product development, promoting "an increase in tradable and internationalizable production"

and providing competitive advantages for Felmica, contributing to entry into new markets.

With this project, Felmica aims to acquire new equipment to improve the structures in terms of the Prospecting,

Extraction, Transformation, Laboratory Control, and Warehouse sections, as well as the acquisition of systems

that will increase the energy efficiency of its processes, improve working conditions, and reduce the environmental

impact of its activity. With the innovations to be implemented in the production process, Felmica will be able to

increase the quality of its products, producing compounds with higher added value, and increase its competitiveness,

strengthening its presence in foreign markets and enabling... Entry into new market segments.

At the end of the project, Felmica intends to launch new products based on quartz, lithium-enriched feldspathic

materials, and other types of lithium-free feldspars, aimed not only at the market where the company already operates

(the ceramic industry and, in particular, the sanitary ware industry in the case of the absence of lithium), but also

at new market segments such as Silestone, paints, and rubber. In the case of lithium-enriched raw materials,

Felmica foresees a significant impact on the manufacturing processes of its clients in the ceramic industry,

since lithium, as an additive, represents an advantage both in terms of process (more efficient) and in terms

of the final product (more resistant).

With the implementation of its strategy and, in particular, this project, Felmica estimates a growth in revenue

of approximately 64%, and exports should increase from 15% to 26%.

Motamineral Minerais Industriais S. A.

Compete 2020- Autonomous projects

Project Designation | AUTONOMOUS TRAINING PROJECTS – Operational Programme Competitiveness and Internationalisation, supported by the ESF, under the terms of the Call for Applications No. 10/SI/2020

Project Number | 113452

Main Objective | OT 8 – Promotion of sustainability and quality of employment and support for worker mobility

Region of Intervention | CENTRAL REGION

Beneficiary Entity | MOTA MINERAL, MINERAIS INDUSTRIAIS, S.A.

Approval Date | 2021-08-04

Start Date | 2021-06-30

End Date | 2023-09-30

Total Eligible Cost | €199 €299.84

Final Incentive | €97,059.84

The introduction of new products to the market, as well as customer response, are key factors in the company's competitiveness and investment, focusing on R&D projects, increasing its production capacity, and continuous improvement. The globalization of the sector and the consequent entry into the market of cheaper products from economies with lower production costs, as well as counterfeiting, puts the competitiveness of European companies at risk. Continuous innovation is therefore the main critical factor for competitiveness in product differentiation/sophistication. The company, in collaboration with some of its main partners (R&D entities and companies), ensures the constant development of products with differentiating characteristics and greater added value, which gives it a leading industrial position.

Thus, this project aims to contribute to the development of people's behavioral skills and attitudes, creating an environment where communication flows and teams function as one. To overcome the need for integration into the digital economy and the dematerialization of processes, it is essential to have people with digital skills, capable of responding to the evolution and investments that the company has made in this field, who feel committed to technological change and who have the active participation of everyone so that the digitalization of the company can happen. This training plan also aims, through the reinforcement of skills for the optimization of production processes, planning, and the introduction of methodologies that allow for increased process efficiency, to respond to the investment in process optimization and layout changes that the company has made. The company's sustainability also involves concern for resource management, not only for the costs involved, but also for respect for the climate, making it important to develop resource-saving attitudes, such as energy, water, or materials. The well-being of workers is also a concern for the company, since the costs are high, as are the investments the company makes in this regard – safe production equipment, individual and collective protection; therefore, it is important that people develop proactive and responsible attitudes that mitigate the risk of accidents. For the strategy to lead the company to initiate processes of change and innovation, it is crucial to have teams that function as solid pillars and agents of the strategy.

Motamineral Minerais Industriais S. A.

Prr

Agenda | ECP – EcoCerâmica e Cristalaria de Portugal

Consortium Leader | VISTA ALEGRE ATLANTIS, S.A.

Agenda Description | An integrated and cross-cutting proposal for the Ceramics and Glassware sectors, focused on their critical competitiveness factors and aiming for improved international positioning. With a focus on four central thematic areas – energy sustainability, circular economy and industrial symbiosis, digital transition and capacity building – it aims to develop new products, processes and services with high added value, based on new cross-sectoral industrial organization models, thus ensuring progression in the international value chain and a focus on higher value-added activities.

Start date | 01/01/2022

Completion date | 30/06/2026

Investment | 118.245.057,52€

Project objectives: To increase the competitiveness of the national ceramics and glass industry, based on factors of innovation, differentiation, and a strong collaborative dynamic and investment in innovation throughout the various segments of the sector's value chain, supported by improving the qualification of its assets.

Results:Products, processes and services (PPS) resulting from the project:

- Conversion of existing furnaces (NG/H2);

- Conversion of existing NG distribution infrastructures to NG/H2;

- Roller furnace;

- Decision support tool for the implementation of heat recovery projects;

- Service and technologies for system reconversion to promote process decarbonization;

- Industrial Park Monitoring Service using non-intrusive methodologies;

- Centralized Logistics Service for waste collection and valorization;

- ECOBLEND GP – New raw material for eco-sustainable ceramic paste for flooring;

- REVVER – New eco-sustainable ceramic paste for wall coverings;

- GRESVER – New eco-sustainable ceramic paste for stoneware tableware;

- Glass with a higher incorporation rate of cullet and other by-products for glass production;

- New Eco-Sustainable Ceramic Paste for Soft Porcelain Tableware;

- New Eco-Sustainable Ceramic Paste for Stoneware Tableware;

- New Eco-Sustainable Ceramic Paste for Porcelain Tiles;

- New Eco-Sustainable Ceramic Paste for Vitreous China Sanitary Ware;

- New production process for low-temperature sintering;

- Soft Porcelain Tableware with Innovative LOFT Porcelain Paste for Reduced Temperature Sintering;

- Stoneware Tableware with Innovative LOFT Stoneware Paste for Reduced Temperature Sintering;

- Porcelain Stoneware Floor Tiles with Innovative LOFT Tile Paste for Reduced Temperature Sintering;

- Sanitary Ware with Innovative Eco-Sustainable Paste;

- New glossy glaze for eco-sustainable sanitary ware adapted to reduced temperature;

- New opaque glaze for eco-sustainable sanitary ware adapted to reduced temperatures;

- National BIM content platform for the Ceramic Industry;

- Digital warehouses for ceramic molds and purlins;

- Digital production system for ceramic product models and purlins;

- Traceability system for ceramic products;

- Data integration platform for the ceramic industry's production chain;

- Interoperability platform;

- New cross-cutting services;

- Online Waste Resource Center platform;

- Waste Resource Management Services;

- Digital Training Academy for the Ceramic and Glass sectors;

- ECOSAN – New Ceramic Paste for eco-sustainable stoneware sanitary ware;

- Development of Hydrogen Transport Containers;

- Optimization of Energy Sustainability in Oxy-hybrid Kilns for the Glassware Sector;

- Intelligent System for Monitoring and Managing Exposure to Chemical Agents in the Ceramic and Glassware Industry;

- Intelligent System for Optimizing Energy Use in the Ceramic and Glassware Industry;

- Development of a Solution to Support the Calibration of Guns in the Glazing Process;

- Quality Control Point;

- Creation of Interactive Spaces that Recreate the Industry of the Future, in a Ceramic Lab Factory Logic.

Beneficiary entity | MOTAMINERAL, MINERAIS INDUSTRIAIS S.A.

Investment | 3 372 267,11€

Motamineral Minerais Industriais S. A.

Compete 2020

Project designation | CAVALI – CADEIA DE VALOR DO LÍTIO

Project code | POCI-01-0247-FEDER-047728

Main objective | Strengthen research, technological development and innovation.

Intervention region | NORTH: 84,01 % e CENTER: 15,99 %

Beneficiary entity | MOTAMINERAL Minerais Industriais, S.A.

Link to the CAVALI Project Website | https://www.clustermineralresources.pt/cavali

Approval date | 2021-05-04

Start date | 2020-07-01

Completion date | 2023-06-30

Total eligible cost |2.838.933,17€

Financial support from the European Union | FEDER | 1.914.712,47 €

The CAVALI Project – LITHIUM VALUE CHAIN, involves a consortium of 6 entities led by MOTAMINERAL, MINERAIS INDUSTRIAIS S.A., composed of 1 Industrial Minerals Company and 5 entities from the Scientific and Technological System.

The CAVALI Project, registered on March 31, 2020, in Call for Proposals No. 17/SI/2019 – Incentive System for Research and Technological Development (SI I&DT), Co-promotion Projects, No. 047728, has as its primary objective to maximize the use of national lithium mineral resources, creating ore beneficiation processes that allow for the complete utilization of existing by-products, with zero waste generation.

Project designation | Independent Training Projects – Operational Programme Competitiveness and Internationalisation, supported by the ESF, under the terms of Call for Applications No. 10/SI/2020

Project number | 113452

Main objective |OT 8 – Promoting sustainability and quality of employment and supporting worker mobility.

Intervention region | CENTER

Beneficiary entity | MOTA MINERAL, MINERAIS INDUSTRIAIS, S.A.

Approval date | 2021-08-04

Start date | 2021-06-30

Completion date | 2023-09-30

Total eligible cost |199 299,84€

Final Incentive | 97 059,84€

Based on the introduction of new products to the market, as well as customer response, key factors in the company's competitiveness and investment focus on R&D projects, increased production capacity, and continuous improvement are key. The globalization of the sector and the consequent entry of cheaper products from economies with lower production costs, as well as counterfeiting, puts the competitiveness of European companies at risk. Continuous innovation is therefore the main critical factor for competitiveness in product differentiation/sophistication. The company, in collaboration with some of its main partners (R&D entities and companies), ensures the constant development of products with differentiating characteristics and higher added value, which gives it a leading industrial position.

Thus, this project aims to contribute to the development of people's behavioral skills and attitudes, creating an environment where communication flows and teams function as one. To overcome the need for integration into the digital economy and the dematerialization of processes, it is essential to have people with digital skills, capable of responding to the evolution and investments that the company has made in this field, who feel committed to technological change and who have the active participation of everyone so that the digitalization of the company can happen. This training plan also aims, through the reinforcement of skills for the optimization of production processes, planning, and the introduction of methodologies that allow for increased process efficiency, to respond to the investment in process optimization and layout changes that the company has made. The company's sustainability also involves concern for resource management, not only for the costs involved, but also for respect for the climate, making it important to develop resource-saving attitudes, such as energy, water, or materials. The well-being of workers is also a concern for the company, since the costs are high, as are the investments the company makes in this regard – safe production equipment, individual and collective protection; therefore, it is important that people develop proactive and responsible attitudes that mitigate the risk of accidents. For the strategy to lead the company to initiate processes of change and innovation, it is crucial to have teams that function as solid pillars and agents of the strategy.

Motamineral Minerais Industriais S. A.

Norte 2020

Project designation | Training for the development of new products with a view to approaching new markets.

Project code | NORTE-02-0853-FEDER-015289

Main objective | 3 – Strengthening the competitiveness of SMEs

Intervention Region | North– Portugal

Beneficiary entity | MOTAMINERAL, MINERAIS INDUSTRIAIS S.A.

Approval date | 2016-04-14

Start date | 2016-06-01

Completion date | 2018-05-31

Total eligible cost | 2.268.000,00€

Financial support from the European Union | 1.134.000,00€

Objectives, activities and expected/achieved results

MotaMineral, SA is a company, established in 1967 and headquartered in Viana do Castelo, dedicated to the

extraction and processing of raw materials, namely kaolin and clay. The company offers a wide range of washed

kaolin products for ceramic applications, special white and red clays, as well as certified sands for the construction

industry.

This investment project aims to strengthen the company's growth nationally and internationally, conquering new

market niches through the development of new products, following improvements in clay and sand processing,

resulting in products with significantly reduced particle size and low moisture content.

In this sense, the company will equip itself with equipment that allows for new processing stages, leading to the

acquisition of new clients in the rubber, cork, paint, and cosmetics sectors.

Mota II Soluções Cerâmicas S. A.

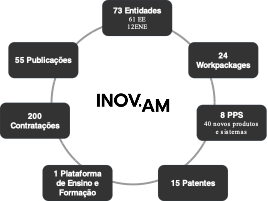

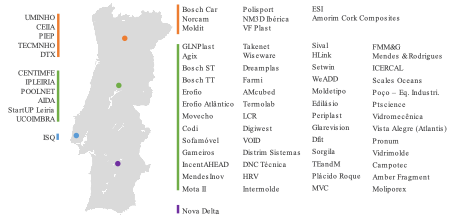

Prr- INOV.AM – Innovation in Additive Manufacturing

AGENDA | INOV.AM – Innovation in Additive Manufacturing

CONSORTIUM LEADER | EROFIO – ENGINEERING AND MOLD MANUFACTURING S.A.

AGENDA DESCRIPTION | INOV.AM arises from the emerging need to stimulate and innovate Portuguese industry, in order to revolutionize and highlight Portugal's potential and competitiveness in the international market, within the scope of additive manufacturing, aiming at the development of new materials, advanced manufacturing and post-production processes, advanced automation and control software, new products and training and capacity building of human resources.

START DATE | 01/07/2022

END DATE | 31/12/2025

AGENDA INVESTMENT | EUR 76,952,903.21

AGENDA INCENTIVE | EUR 53,267,360.63

BENEFICIARY ENTITY | MOTA II SOLUÇÕES CERÂMICAS, SA

BENEFICIARY INVESTMENT | EUR 564,774.60

BENEFICIARY INCENTIVE | EUR 307,479.12

Mota II Soluções Cerâmicas S. A.

Compete 2020- Autonomous Training Projects

Project Title | Autonomous Training Projects

Operational Programme Competitiveness and Internationalisation, supported by the ESF, under the terms of Call for Applications No. 10/SI/2020

Project Code | 113454

Main Objective | OT 8 – Promotion of sustainability and quality of employment and support for worker mobility

Region of Intervention | Centre

Beneficiary Entity | Mota II Soluções Cerâmicas, SA

Approval Date | 28-12-2021

Start Date | 21-07-2021

Completion Date | 30-09-2023

Total Eligible Cost | €194,738.40

Total Eligible Cost | €94,838.40

The introduction of new products to the market, as well as customer response, are key factors in the company's competitiveness and investment, focusing on R&D projects, increasing its production capacity, and continuous improvement. The globalization of the sector and the consequent entry into the market of cheaper products from economies with lower production costs, as well as counterfeiting, puts the competitiveness of European companies at risk. Continuous innovation is therefore the main critical factor for competitiveness in product differentiation/sophistication. The company, in collaboration with some of its main partners (R&D entities and companies), ensures the constant development of products with differentiating characteristics and greater added value, which gives it a leading industrial position.

Thus, this project aims to contribute to the development of people's behavioral skills and attitudes, creating an environment where communication flows and teams function as one. To overcome the need for integration into the digital economy and the dematerialization of processes, it is essential to have people with digital skills, capable of responding to the evolution and investments that the company has made in this field, who feel committed to technological change and who have the active participation of everyone so that the digitalization of the company can happen. This training plan also aims, through the reinforcement of skills for the optimization of production processes, planning, and the introduction of methodologies that allow for increased process efficiency, to respond to the investment in process optimization and layout changes that the company has made. The company's sustainability also involves concern for resource management, not only for the costs involved, but also for respect for the climate, making it important to develop resource-saving attitudes, such as energy, water, or materials. The well-being of workers is also a concern for the company, since the costs are high, as are the investments the company makes in this regard – safe production equipment, individual and collective protection; therefore, it is important that people develop proactive and responsible attitudes that mitigate the risk of accidents. For the strategy to lead the company to initiate processes of change and innovation, it is crucial to have teams that function as solid pillars and agents of the strategy.

Mota II Soluções Cerâmicas S. A.

Compete 2020- FLOWARE

Project Title | FLOWARE – Research and Development of a Flameware Product Line

Project Code | POCI-01-0247-FEDER-017668

Main Objective | To strengthen research, technological development and innovation

Region of Intervention | Central Portugal

Beneficiary Entity | Grestel – Produtos Cerâmicos, S.A.; Mota II Soluções Cerâmicas, SA

Approval Date | 18-10-2016

Start Date | 16-03-2016

Completion Date | 31-12-2018

Total Eligible Cost | €1,021,852.74

European Union Financial Support | €586,408.09, through the European Regional Development Fund

Objectives, activities and expected results

With the implementation of the FLOWARE project, the proposing consortium, formed by the companies Grestel and Mota II, intends to develop two pastes (plastic and slip) and three glazes (transparent, opaque and frosted), to manufacture a product capable of withstanding the thermomechanical stresses resulting from the direct action of the flame of domestic and industrial stove burners.

Specifically, the aim is to obtain:

Two stoneware pastes (plastic paste for counter-molding and pressing, and slip for filling) with water absorption ≤1%, MOR (3 points) greater than 35 MPa, fracture toughness KC ≥1 MPam-1/2 and CTE between 20×10-7 K-1 and 30×10-7 K-1, in the temperature range of 20 – 800ºC;

Three glazes (transparent, opaque and matte), with CTE between 15×10-7 K-1 and 25×10-7 K-1, in the same temperature range as above, softening temperature above 800ºC and fracture toughness KIC ≥0.75 MPam-1/2; Nine finished stoneware products by single firing, corresponding to the three shaping methods used (pressing, counter-molding and filling) and the three glazes (opaque, transparent and matte), with the most suitable shape, microstructure and mechanical and thermal properties, to withstand the thermal shocks resulting from their exposure to the flame of domestic and industrial gas stove burners.

Three final products, to be chosen from the previous nine (1 paste + 1 shaping method and 3 glazes), suitable to be produced and marketed by Grestel in a phase subsequent to the completion of the project, in accordance with the requirements established by the project for Flameproof tableware.

Results achieved

With the completion of the project, the proposing consortium developed two pastes (plastic paste and slip) and three glazes (transparent, opaque and matte), to manufacture products capable of withstanding the thermomechanical stresses resulting from their use, particularly when subjected to the direct action of the flame of domestic and industrial burners. Initially, some constraints were raised, namely the difficulty in optimizing the design level of the model for pottery pieces, as well as the unforeseen difficulties in obtaining raw materials on the market.

The shift from pilot-scale prototypes to industrial-scale production brought some problems that had to be overcome:

Slip casting – Difficulty in transforming the plastic paste composition into a filler paste with the same characteristics as FLOWARE. Rheological problems and wall formation time. Pieces with many pores.

Immersion glazing – easy rheological adjustment but with difficulties in achieving homogeneous glaze layers, which causes differences in the behavior of the pieces in the flame.

Kiln – Difficulty in controlling temperature gradients in a large intermittent kiln when the product requires very tight temperature gradients. Tuning problems due to the cooling plateau, which implied a special intervention by the kiln supplier to allow programming of this cooling plateau.

Large-scale factory-level tests were conducted involving all sectors of FLOWARE ceramic tile production.

Based on information from the University of Aveiro regarding the behavior of FLOWARE tiles during the tests, design corrections were made, particularly in the design of the frets, as well as in the thickness of the bottom and wall of the tiles.

With the production of larger series, some tiles were put into service in a domestic and industrial environment to obtain the real performance of the tiles and their behavior over time.

In terms of disseminating the results, an article was published in the journal cfi – Ceramic Forum International [edition cfi/Ber. DKG 95 (2018) No. 9-10], entitled “MOTA Ceramic Solutions (MCS) Low Expansion Ceramic Bodies and Glazes for Ceramic Flameware Manufacture,” and the results were disseminated at specific events.

Mota II Soluções Cerâmicas S. A.

Compete 2020- CASA: CERAMIC ALTERNATIVE STRONG ARTICLE

Project Designation | CASA: CERAMIC ALTERNATIVE STRONG ARTICLE

Project Code | 003490

Main Objective | 3 – Strengthen the competitiveness of SMEs

Region of Intervention | Central Region

Beneficiary Entity | Vista Alegre Atlantis, SA (VAA); Mota II Soluções Cerâmicas, SA (MSC)

Approval Date | 2015-09-22

Start Date | 2016-01-01

Completion Date | 2018-07-01

Total Eligible Cost | R$ 1,321,431.91

Financial Support from the European Union | €774,905.83

Objectives, activities and expected/achieved results

The “CASA – Ceramic Alternative Strong Article” is a research and development project promoted by Vista Alegre Atlantis, SA (VAA) and Mota II Soluções Cerâmicas, S.A. (MSC).

The promoters aim to develop a new ceramic product with visual characteristics very similar to traditional earthenware, but simultaneously with significantly improved technical characteristics. To this end, the new product will be based on a new stoneware paste formulation with high mechanical resistance and low porosity, which will be colored and coated with a completely transparent glaze, and subjected to a single firing operation (monofiring), thus reducing energy consumption.

The product should exhibit high mechanical resistance, low porosity, and a smaller thickness than stoneware pieces (approximately 4-6 mm, similar to porcelain), giving the product greater durability and facilitating its daily use as a tableware item.

The CASA project's main objective is to develop new tableware products with a high degree of color richness, similar to that of earthenware, but with sufficient mechanical strength to be used under conditions of high mechanical and thermomechanical stress.

Mota II Soluções Cerâmicas S. A.

Centro 2020

Project designation | ePorcel – Research and Development of New Fine Porcelain Tableware Products

Project code | CENTRO2030-FEDER-01167800

Main objective | Research & Development of New Fine Porcelain Tableware Products with Disruptive Performance in Mitigating Adverse Environmental Impacts

Intervention Region | Center

Beneficiary entity | Porcel – Ind. Portuguesa de Porcelanas, SA / Mota II Sol. Cerâmicas, SA / Univ. Aveiro

Start date | 2025-01-01

Completion date | 2027-12-31

Total eligible cost | 1 099 756,48 Euros

Financial support from the European Union | 763 379,69 Euros

Objectives, activities and expected/achieved results

The ePorcel project aims to develop a porcelain tableware product with significantly minimized CO2 emissions, coupled with a highly energy-efficient sintering process. This will achieve unparalleled performance in the sector, thus supporting differentiated factors of competitiveness and sustainability in the market.

Porcel, in partnership with Mota II and the University of Aveiro, intends to leverage these goals by acting along the following lines:

– Changing the firing process from a gas kiln to an electric kiln;

– Reducing the firing temperature from 1400ºC to temperatures below 1300ºC, while maintaining similar characteristic parameters of the porcelain.

Mota II Soluções Cerâmicas S. A.

Compete 2020

Project designation | INDIVIDUAL PROJECTS – Internationalization: Market diversification and international marketing of Mota II Soluções Cerâmicas, S.A.

Project code | POCI-02-0752-FEDER-013983

Main objective | Strengthening the competitiveness of small and medium-sized enterprises

Intervention Region | Center

Beneficiary entity | Mota II Soluções Cerâmicas, S.A.

Approval date | 2016-01-26

Start date | 2015-10-01

Completion date | 2018-03-31

Total eligible cost | €699.800,00

Financial support from the European Union | €314.910,00

Objectives, activities and expected/achieved results

A MOTA II SOLUÇÕES CERAMICAS, S.A., This company, located in the Aveiro district, began operations in 1998 but belongs to a group of companies (Grupo Mota) with over 60 years of experience. The company's mission is to provide the highest quality raw materials, compounds, and technical support to the ceramics industry.

In a pre-project phase, the company already has some export activity, with the international market representing approximately 36% of its total revenue.

The strategic objectives of the project are:

Greater presence in international markets, with enhanced customer service in those markets where the company is already present;

Process optimization: effectiveness in the exploitation of natural resources, efficiency in their transformation, and constant innovation in customer offerings;

Continuous commitment to providing technical support to client companies, from product conception to after-sales service.

The planned action types are as follows:

Knowledge of foreign markets (Trade Fairs/Exhibitions), through participation in various international trade fairs;

International marketing, namely through the production of a promotional video for trade fairs and catalog production services (photographic report, design, printing);

Introduction of a new organizational method in commercial practices or external relations, such as the implementation of a CRM.

From a post-project perspective and through entry into new markets, Mota II anticipates that the international market will represent approximately 42% of its Total Business Volume.

Project designation | CASA: CERAMIC ALTERNATIVE STRONG ARTICLE

Project code | 003490

Main objective | 3 – Strengthening the competitiveness of SMEs

Intervention Region | Center

Beneficiary entity | Vista Alegre Atlantis, SA (VAA); Mota II Soluções Cerâmicas, S.A. (MSC).

Approval date | 2015-09-22

Start date | 2016-01-01

Completion date | 2018-07-01

Total eligible cost | 1.321.431,91 €

Financial support from the European Union | 774.905,83 €

Objectives, activities and expected/achieved results

The “CASA – Ceramic Alternative Strong Article” is a research and development project promoted by Vista Alegre Atlantis, SA (VAA) and Mota II Soluções Cerâmicas, S.A. (MSC).

The promoters aim to develop a new ceramic product with visual characteristics very similar to traditional earthenware, but simultaneously with significantly improved technical characteristics. To this end, the new product will be based on a new stoneware paste formulation with high mechanical resistance and low porosity, which will be colored and coated with a completely transparent glaze, and subjected to a single firing operation (monofiring), thus reducing energy consumption.

The product should exhibit high mechanical resistance, low porosity, and a smaller thickness than stoneware pieces (approximately 4-6 mm, similar to porcelain), giving the product greater durability and facilitating its daily use as a tableware item.

The CASA project's main objective is to develop new tableware products with a high degree of color richness, similar to that of earthenware, but with sufficient mechanical strength to be used under conditions of high mechanical and thermomechanical stress.

Project designation | FLOWARE – Research and development of a line of flame-retardant stoneware products.

Project code | POCI-01-0247-FEDER-017668

Main objective | Strengthen research, technological development and innovation.

Intervention Region | Center

Beneficiary entity | Grestel – Produtos Cerâmicos, S.A.; Mota II Soluções Cerâmicas, S.A.

Approval date | 18-10-2016

Start date | 16-03-2016

Completion date | 31-12-2018

Total eligible cost | 1.021.852,74 Euros

Financial support from the European Union | 586,408.09 Euros, through the European Regional Development Fund

Objectives, activities and expected results

With the FLOWARE project, the proposing consortium, formed by the companies Grestel and Mota II, intends to develop two pastes (plastic and slip) and three glazes (transparent, opaque and frosted), to manufacture a product capable of withstanding the thermomechanical stresses resulting from the direct action of the flame from domestic and industrial stove burners.

Specifically, the goal is to achieve:

- Two stoneware pastes (plastic paste for counter-molding and pressing and slip for filling) with water absorption ≤1%, MOR (3 points) greater than 35 MPa, fracture toughness KC ≥1 MPam-1/2 and CTE between 20×10-7 K-1 and 30×10-7 K-1, in the temperature range 20 – 800ºC);

- Three glazes (transparent, opaque and matte), with CTE between 15×10-7 K-1 and 25×10-7 K-1, in the same temperature range as above, softening temperature above 800ºC and fracture toughness KIC ≥0.75 MPam-1/2;

- Nine finished stoneware products by single firing, corresponding to the three shaping methods used (pressing, counter-molding and filling) and the three glazes (opaque, transparent and matte), with the most suitable shape, microstructure and mechanical and thermal properties to withstand the thermal shocks resulting from their exposure to the flame of domestic and industrial gas stove burners.

- Three final products, to be chosen from among the nine above (1 paste + 1 shaping method and 3 glazes), suitable to be produced and marketed by Grestel at a later stage after the project is completed, in accordance with the requirements established by the project for Flameproof tableware.

Results achieved

With the completion of the project, the proposing consortium developed two pastes (plastic paste and slip) and three glazes (transparent, opaque, and matte) to manufacture products capable of withstanding the thermomechanical stresses resulting from their use, particularly when subjected to the direct action of the flame from domestic and industrial burners.

Initially, some constraints arose, namely the difficulty in optimizing the design level of the model for pottery pieces, as well as the unforeseen difficulties in obtaining raw materials on the market.

The shift from pilot-scale prototypes to industrial-scale production brought some problems that had to be overcome:

- Slip casting – Difficulty in transforming the plastic paste composition into a filler paste with the same characteristics as FLOWARE. Rheological problems and wall formation time. Pieces with many pores.

- Immersion glazing – easy rheological adjustment but with difficulties in having homogeneous glaze layers, which causes differences in the behavior of the pieces in the flame.

- Kiln – Difficulty in controlling temperature gradients in a large intermittent furnace when the product requires very tight temperature gradients. Tuning problems due to the cooling plateau, which implied a special intervention by the furnace supplier to allow programming of this cooling plateau.

Large-scale factory-level tests were conducted involving all sectors of FLOWARE ceramic tile production.

Based on information from the University of Aveiro regarding the behavior of FLOWARE tiles during the tests, design corrections were made, particularly in the design of the frets, as well as in the thickness of the bottom and wall of the tiles.

With the production of larger series, some tiles were put into service in a domestic and industrial environment to obtain the real performance of the tiles and their behavior over time.

In terms of disseminating the results, an article was published in the journal cfi – Ceramic Forum International [edition cfi/Ber. DKG 95 (2018) No. 9-10], entitled “MOTA Ceramic Solutions (MCS) Low Expansion Ceramic Bodies and Glazes for Ceramic Flameware Manufacture,” and the results were disseminated at specific events.

Project designation | Autonomous Training Projects

Operational Programme Competitiveness and Internationalisation, supported by the ESF, under the terms of Call for Applications No. 10/SI/2020

Project code | 113454

Main objective | OT 8 – Promoting sustainability and quality of employment and supporting worker mobility.

Intervention Region | Center

Beneficiary entity | Mota II Soluções Cerâmicas, S.A.

Approval date | 28-12-2021

Start date | 21-07-2021

Completion date | 30-09-2023

Total eligible cost | 194.738,40 Euros

Total eligible cost | 94.838,40 Euros

Based on the introduction of new products to the market, as well as customer response, key factors in the company's competitiveness and investment focus on R&D projects, increased production capacity, and continuous improvement are key. The globalization of the sector and the consequent entry of cheaper products from economies with lower production costs, as well as counterfeiting, puts the competitiveness of European companies at risk. Continuous innovation is therefore the main critical factor for competitiveness in product differentiation/sophistication. The company, in collaboration with some of its main partners (R&D entities and companies), ensures the constant development of products with differentiating characteristics and higher added value, which gives it a leading industrial position.

Thus, this project aims to contribute to the development of people's behavioral skills and attitudes, creating an environment where communication flows and teams function as one. To overcome the need for integration into the digital economy and the dematerialization of processes, it is essential to have people with digital skills, capable of responding to the evolution and investments that the company has made in this field, who feel committed to technological change and who have the active participation of everyone so that the digitalization of the company can happen. This training plan also aims, through the reinforcement of skills for the optimization of production processes, planning, and the introduction of methodologies that allow for increased process efficiency, to respond to the investment in process optimization and layout changes that the company has made. The company's sustainability also involves concern for resource management, not only for the costs involved, but also for respect for the climate, making it important to develop resource-saving attitudes, such as energy, water, or materials. The well-being of workers is also a concern for the company, since the costs are high, as are the investments the company makes in this regard – safe production equipment, individual and collective protection; therefore, it is important that people develop proactive and responsible attitudes that mitigate the risk of accidents. For the strategy to lead the company to initiate processes of change and innovation, it is crucial to have teams that function as solid pillars and agents of the strategy.

Mota II Soluções Cerâmicas S. A.

Prr- Eco- Eco-Ceramics and Crystalware of Portugal

Agenda | ECP – EcoCeramics and Crystalware of Portugal

Consortium Leader | VISTA ALEGRE ATLANTIS, SA

Agenda Description | An integrated and transversal proposal for the Ceramics and Crystalware sectors, focused on their critical competitiveness factors and aiming for an improvement in international positioning. With a focus on 4 central thematic areas – energy sustainability, circular economy and industrial symbiosis, digital transition and capacity building – it focuses on the development of new products, processes and services with high added value, based on new cross-sectoral industrial organization models, thus ensuring progression in the international value chain and a focus on higher value-added activities.

Start Date | 01/01/2022

End Date | 30/06/2026

Investment | R$ 118,245,057.52

Project Objectives: To increase the competitiveness of the national ceramics and glass industry, based on innovation, differentiation, and a strong collaborative dynamic and investment in innovation across the various segments of the sector's value chain, supported by improving the qualification of its assets.

Results: Products, processes and services (PPS) resulting from the project:

- Conversion of existing kilns (NG/H2);

- Conversion of existing NG distribution infrastructures to NG/H2;

- Roller Kiln;

- Decision support tool for implementing heat recovery projects;

- Service and technologies for system reconversion to promote process decarbonization;

- Industrial Park Monitoring Service using non-intrusive methodologies;

- Centralized Logistics Service for waste collection and valorization;

- ECOBLEND GP – New raw material for eco-sustainable ceramic paste for flooring;

- REVVER – New Ceramic Paste for Eco-sustainable Coatings;

- GRESVER – New Ceramic Paste for Eco-sustainable Stoneware Tableware;

- Glass with a higher incorporation rate of cullet and other by-products for glass production;

- New Eco-Sustainable Ceramic Paste for Soft Porcelain Tableware;

- New Eco-Sustainable Ceramic Paste for Stoneware Tableware;

- New Eco-Sustainable Ceramic Paste for Porcelain Tiles;

- New Eco-Sustainable Ceramic Paste for Vitreous China Sanitary Ware;

- New production process for low-temperature sintering;

- Soft Porcelain Tableware with Innovative LOFT Porcelain Paste for Reduced Temperature Sintering;

- Stoneware Tableware with Innovative LOFT Stoneware Paste for Reduced Temperature Sintering;

- Porcelain Stoneware Flooring with Innovative LOFT Tile Paste for Reduced Temperature Sintering;

- Sanitary Ware with Innovative Eco-Sustainable Paste;

- New glossy glaze for eco-sustainable sanitary ware adapted to reduced temperatures;

- New matte glaze for eco-sustainable sanitary ware adapted to reduced temperatures;

- National BIM content platform for the Ceramic Industry;

- Digital warehouses for ceramic molds and purlins;

- Digital production system for ceramic product models and purlins;

- Traceability system for ceramic products;

- Data integration platform for the ceramic industry's production chain;

- Interoperability Platform;

- New cross-cutting services;

- Online Waste Resource Center Platform;

- Waste Resource Management Services;

- Digital Training Academy for the Ceramics and Glass sectors;

- ECOSAN – New Ceramic Paste for Sanitary Ware in eco-sustainable stoneware;

- Development of Hydrogen Transport Containers;

- Optimization of Energy Sustainability in Oxy-hybrid Kilns for the Glassware sector;

- Intelligent System for Monitoring and Managing Exposure to Chemical Agents in the Ceramics and Glassware Industry;

- Intelligent System for Optimizing Energy Use in the Ceramics and Glassware Industry;

- Development of a Solution to Support the Calibration of Guns in the Glazing Process;

- Quality Control Point;

- Creation of Interactive Spaces that Recreate the Industry of the Future, in a Ceramic Lab Factory Logic.

Beneficiary Entity | MOTA II SOLUÇÕES CERÂMICAS, SA

Investment | 8,642,871.13€

Mota Pastas Cerâmicas S. A.

Compete 2020

Project designation | Autonomous Training Projects

Operational Programme Competitiveness and Internationalisation, supported by the ESF, under the terms of Call for Applications No. 10/SI/2020

Project code | 113452

Main objective | OT 8 – Promoting sustainability and quality of employment and supporting worker mobility.

Intervention region | CENTER

Beneficiary entity | MOTA PASTAS CERÂMICAS, S.A.

Approval date | 2021-12-28

Start date | 2021-07-21

Completion date | 2023-09-30

Total eligible cost | 72.193,56€

Financial support from the European Union | FEDER | 35 158,56€

The introduction of new products to the market, as well as customer response, are key factors in the company's competitiveness and investment, focusing on R&D projects, increasing its production capacity, and continuous improvement. The globalization of the sector and the consequent entry into the market of cheaper products from economies with lower production costs, as well as counterfeiting, puts the competitiveness of European companies at risk. Continuous innovation is therefore the main critical factor for competitiveness in product differentiation/sophistication. The company, in collaboration with some of its main partners (R&D entities and companies), ensures the constant development of products with differentiating characteristics and higher added value, which gives it a leading industrial position.

Thus, this project aims to contribute to the development of people's behavioral skills and attitudes, creating an environment where communication flows and teams function as one. To overcome the need for integration into the digital economy and the dematerialization of processes, it is essential to have people with digital skills, capable of responding to the evolution and investments that the company has made in this field, who feel committed to technological change and who have the active participation of everyone, so that the company's digitalization can happen. This training plan also targets, through the reinforcement of skills for the optimization of production processes, planning, and the introduction of methodologies that allow for increased process efficiency, in response to the investment in process optimization and layout changes that the company has made. The company's sustainability also involves concern for resource management, not only for the costs involved, but also for respect for the climate, making it important to develop attitudes of resource conservation, such as energy, water, or materials. Employee well-being is also a concern for the company, given the high costs and investments involved – safe production equipment, personal and collective protection. Therefore, it's important that employees develop proactive and responsible attitudes that mitigate the risk of accidents. For the strategy to lead the company to initiate processes of change and innovation, it's crucial to have teams that function as solid pillars and agents of the strategy.

Mota Pastas Cerâmicas S. A.

Centro 2020

Project designation | LIFE4STONE: Recovery of waste and by-products from the transformation of natural stone into construction products.

Project code | CENTRO-01-0247-FEDER-047067

Main objective |OT1 – Strengthen research, technological development and innovation.

Intervention region | CENTER

Beneficiary entity | MVC – MÁRMORES DE ALCOBAÇA LDA

Approval date | 2020-12-18

Start date | 2020-12-01

Completion date | 2023-06-30

Total eligible cost |661 547,11€

Financial support from the European Union | FEDER | 468 071,23€

The objective of the LIFE4STONE project is to develop solutions for the reuse of waste generated in the extraction and cutting of ornamental rocks, through its incorporation into higher value-added materials, and contributing to the resolution of one of the main constraints of the ornamental rock industry, in both its components (extraction and processing).

A significant portion of the waste produced takes the form of sludge, consisting of very small powders from the cutting and sawing of the stone, and larger granular pieces.

The aim is to study and characterize solutions in two areas to be developed in parallel: the incorporation of sludge into pastes used as raw material in the ceramic industry and the development of composites that integrate the waste and allow the production of urban furniture pieces.

Mota Pastas Cerâmicas S. A.

Prr

Agenda | ECP – Eco-Ceramics and Crystalware of Portugal

Consortium Leader | VISTA ALEGRE ATLANTIS, S.A.

Agenda Description | An integrated and cross-cutting proposal for the Ceramics and Glassware sectors, focused on their critical competitiveness factors and aiming for improved international positioning. With a focus on four central thematic areas – energy sustainability, circular economy and industrial symbiosis, digital transition and capacity building – it aims to develop new products, processes and services with high added value, based on new cross-sectoral industrial organization models, thus ensuring progression in the international value chain and a focus on higher value-added activities.

Start date | 01/01/2022

Completion date | 30/06/2026

Investment | 118.245.057,52€

Project objectives: TTo increase the competitiveness of the national ceramics and glass industry, based on factors of innovation, differentiation, and a strong collaborative dynamic and investment in innovation throughout the various segments of the sector's value chain, supported by improving the qualification of its assets.

Results: Products, processes and services (PPS) resulting from the project:

1. Conversion of existing furnaces (NG/H2);

2. Conversion of existing NG distribution infrastructures to NG/H2;

3. Roller furnace;

4. Decision support tool for the implementation of heat recovery projects;

5. Service and technologies for system reconversion to promote process decarbonization;

6. Industrial Park Monitoring Service using non-intrusive methodologies;

7. Centralized Logistics Service for waste collection and valorization;

8. ECOBLEND GP – New raw material for eco-sustainable ceramic paste for flooring;

9. REVVER – New eco-sustainable ceramic paste for wall coverings;

10. GRESVER – New eco-sustainable ceramic paste for stoneware tableware;

11. Glass with a higher incorporation rate of cullet and other by-products for glass production;

12. New Eco-Sustainable Ceramic Paste for Soft Porcelain Tableware;

13. New Eco-Sustainable Ceramic Paste for Stoneware Tableware;

14. New Eco-Sustainable Ceramic Paste for Porcelain Tiles;

15. New Eco-Sustainable Ceramic Paste for Vitreous China Sanitary Ware;

16. New production process for low-temperature sintering;

17. Soft Porcelain Tableware with Innovative LOFT Porcelain Paste for Reduced Temperature Sintering;

18. Stoneware Tableware with Innovative LOFT Stoneware Paste for Reduced Temperature Sintering;

19. Porcelain Stoneware Floor Tiles with Innovative LOFT Tile Paste for Reduced Temperature Sintering;

20. Sanitary Ware with Innovative Eco-Sustainable Paste;

21. New glossy glaze for eco-sustainable sanitary ware adapted to reduced temperature;

22. New opaque glaze for eco-sustainable sanitary ware adapted to reduced temperatures;

23. National BIM content platform for the Ceramic Industry;

24. Digital warehouses for ceramic molds and purlins;

25. Digital production system for ceramic product models and purlins;

26. Traceability system for ceramic products;

27. Data integration platform for the ceramic industry's production chain;

28. Interoperability platform;

29. New cross-cutting services;

30. Online Waste Resource Center platform;

31. Waste Resource Management Services;

32. Digital Training Academy for the Ceramic and Glass sectors;

33. ECOSAN – New Ceramic Paste for eco-sustainable stoneware sanitary ware;

34. Development of Hydrogen Transport Containers;

35. Optimization of Energy Sustainability in Oxy-hybrid Kilns for the Glassware Sector;

36. Intelligent System for Monitoring and Managing Exposure to Chemical Agents in the Ceramic and Glassware Industry;

37. Intelligent System for Optimizing Energy Use in the Ceramic and Glassware Industry;

38. Development of a Solution to Support the Calibration of Guns in the Glazing Process;

39. Quality Control Point;

40. Creation of Interactive Spaces that Recreate the Industry of the Future, in a Ceramic Lab Factory Logic.

Beneficiary entity | MOTA PASTAS CERÂMICAS S.A.

Investment | 4 651 598,09€